How to Locate and Replace the Cummins ISX Sensor for Optimal Performance

What is a Cummins ISX sensor location diagram? The Cummins ISX sensor is an important component of the engine system, as it helps to ensure optimal performance. If the sensor is not functioning properly, it can lead to decreased fuel efficiency and increased emissions. Therefore, it is important to locate and replace the Cummins ISX sensor for optimal performance.

To locate the Cummins ISX sensor, first, identify where your engine’s ECM (Engine Control Module) is located. The ECM will be located near the firewall on most vehicles. Once you have identified where your ECM is located, look for a small black box with two wires connected to it; this will be your Cummins ISX Sensor.

Once you have identified and located the Cummins ISX Sensor, you can begin replacing it with a new one. To do this, first disconnect both wires from the old sensor and then remove any mounting hardware that may be holding it in place. Next, take out your new replacement part and connect both wires back into their respective ports on the new part before securing any mounting hardware back into place if necessary. Finally, start up your vehicle’s engine to make sure that everything has been installed correctly and that there are no issues with its operation before driving off again safely.

By following these steps carefully when locating and replacing a faulty or worn-out Cummins ISX Sensor for optimal performance in your vehicle’s engine system (including other issues with the Cummins SCR catalyst) will help ensure that you get maximum fuel efficiency while also reducing emissions levels significantly.

Troubleshooting Common Issues with the Cummins ISX Sensor Location Diagram

The Cummins ISX Sensor Location Diagram is a useful tool for troubleshooting common issues with the engine. However, it can be difficult to interpret the diagram correctly if you are unfamiliar with the system. To help you understand and use this diagram effectively, here are some tips for troubleshooting common issues:

1. Check all connections: Make sure that all of the sensors and wiring harnesses are securely connected to their respective components. If any of these connections have become loose or disconnected, they will need to be reattached before further diagnosis can take place.

2. Verify sensor readings: Using a multimeter or other diagnostic tool, check that each sensor is providing accurate readings when compared to its expected values in the Cummins ISX Sensor Location Diagram. If any of these readings are off by more than 10%, then there may be an issue with either the sensor itself or its connection to other components in the system.

3. Inspect wiring harnesses: Visually inspect all wiring harnesses for signs of damage such as fraying or corrosion which could cause inaccurate readings from sensors connected through them. If any damage is found, replace those sections of wire as soon as possible before continuing the diagnosis on other parts of the system.

4. Check power supply: Ensure that each component has an adequate power supply by checking voltage levels at various points throughout your engine’s electrical system using a multimeter or other diagnostic tool. Low voltage levels could indicate an issue with either your battery or alternator which should be addressed immediately before further diagnosis takes place.

Following these steps should help you diagnose the most common issues related to your Cummins ISX Sensor Location Diagram quickly and accurately so that you can get back on track quickly and safely.

Exploring the Benefits of Upgrading to a Cummins ISX Sensor Location Diagram

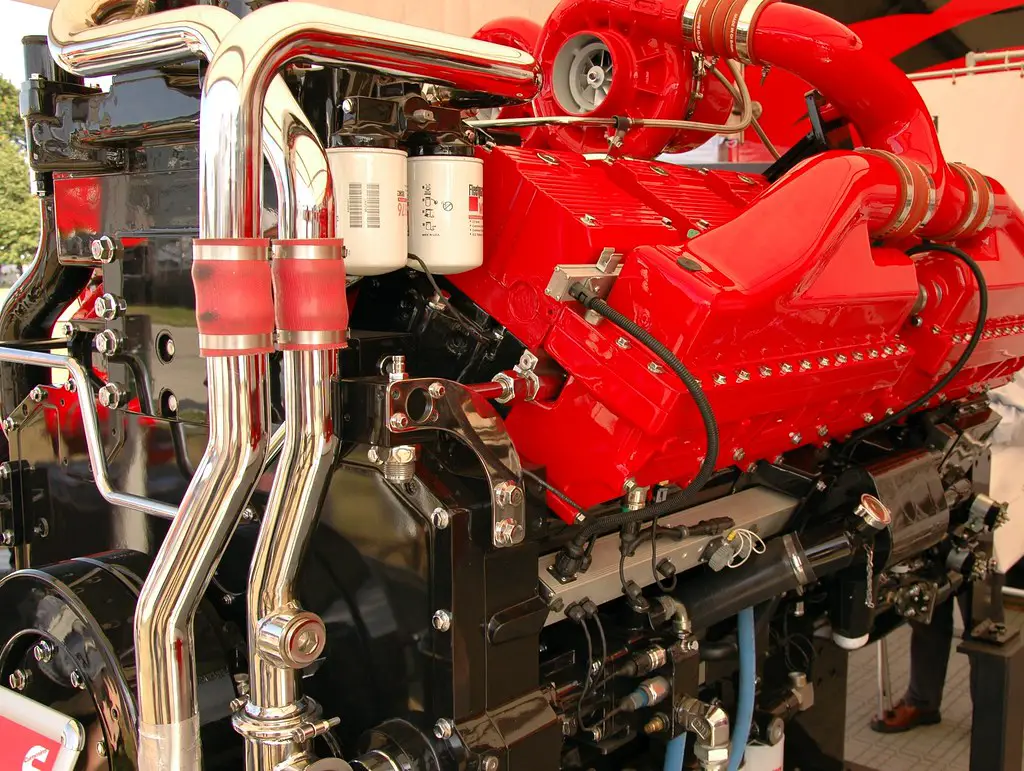

Upgrading to a Cummins ISX engine can provide numerous benefits for those in the transportation industry (including with the new 6.7 Cummins engine). One of the most important advantages is the improved sensor location diagram. This diagram provides an easy-to-understand visual representation of where each sensor is located on the engine, making it easier to identify and troubleshoot any potential issues.

The Cummins ISX sensor location diagram includes detailed information about each component, including its size, shape, and function. This makes it easier for technicians to quickly identify which sensors are malfunctioning or need replacing. Additionally, this diagram also helps technicians determine which parts are compatible with other components to ensure that all parts work together properly and efficiently.

The Cummins ISX sensor location diagram also includes helpful diagrams that show how different components interact with one another. This allows technicians to easily understand how different systems work together and make sure they are functioning correctly before attempting repairs or replacements.

Finally, this upgraded system offers improved accuracy when diagnosing problems with sensors or other components on the engine. The diagrams provide precise measurements so that technicians can accurately diagnose any issues without having to guess at what might be wrong with a particular part or system on the engine.

Overall, upgrading to a Cummins ISX engine provides numerous benefits for those in the transportation industry due largely in part to its improved sensor location diagram which offers detailed information about each component as well as helpful diagrams showing how different systems interact with one another for better accuracy when diagnosing problems on engines.

Understanding the Different Types of Sensors Used in a Cummins ISX System

The Cummins ISX system is a powerful and reliable engine control system used in many commercial vehicles. It relies on a variety of sensors to monitor the performance of the engine and ensure it is running optimally. Understanding the different types of sensors used in this system can help you better maintain your vehicle and keep it running smoothly.

- The most common type of sensor used in a Cummins ISX system is an oxygen sensor, also known as an O2 sensor. This device measures the amount of oxygen present in the exhaust gases produced by the engine, allowing for precise fuel-air mixture adjustments to be made for optimal performance. The O2 sensor also helps reduce emissions by ensuring that only clean exhaust gases are released into the atmosphere.

- Another important type of sensor found in a Cummins ISX system is a pressure sensor, which measures various pressures within the engine such as oil pressure (when you’re using Cummins diesel engine oil), fuel pressure, and turbocharger boost pressure. These sensors provide valuable information about how well your engine is performing and can alert you to any potential problems before they become serious issues.

- Temperature sensors are also essential components of any Cummins ISX system as they measure temperatures throughout various parts of your vehicle’s engine such as coolant temperature, intake air temperature, exhaust gas temperature, and more. By monitoring these temperatures closely you can ensure that your vehicle’s cooling systems are functioning properly and prevent overheating or other damage from occurring due to excessive heat buildup within your engine’s components.

- Finally, speed sensors are another important component found within many Cummins ISX systems as they measure wheel speed which allows for accurate calculation of distance traveled by your vehicle over time or during specific trips or journeys taken with it. This data can be invaluable when diagnosing potential problems with your vehicle’s transmission or other drivetrain components since it provides an accurate record of how much wear has been placed on them over time due to use at varying speeds or under different conditions while driving on roads or highways with varying terrain types or inclines/declines along them respectively.

In conclusion, understanding all these different types of sensors used in a Cummins ISX System will help you better maintain its performance so that you get maximum efficiency out of its use while minimizing emissions released into our environment from its operation at all times too.

Tips for Maintaining Your Cummins ISX Sensor Location Diagram for Maximum Efficiency

1. Regularly inspect the Cummins ISX Sensor Location Diagram for any signs of wear or damage. If any components appear to be worn or damaged, replace them immediately to ensure maximum efficiency.

2. Ensure that all connections are properly secured and that all wiring is in good condition. Loose connections can cause a decrease in performance and may even lead to system failure if not addressed promptly.

3. Keep the Cummins ISX Sensor Location Diagram clean and free from dust, dirt, and debris by regularly wiping it down with a soft cloth or compressed air canister. This will help keep the diagram functioning optimally for longer periods of time without needing repairs or replacements as often as it would otherwise need them if left unclean for extended periods of time.

4. Make sure that all sensors are properly calibrated according to manufacturer specifications before use to ensure accurate readings from each sensor on the diagram at all times during the operation of your engine system.

5. Store your Cummins ISX Sensor Location Diagram in a safe place when not in use so that it does not become damaged due to exposure to extreme temperatures, moisture, dust, dirt, etc., which could potentially cause malfunctioning of its components over time if left unchecked for too long periods of time without proper maintenance being performed on it regularly.