How LS Engines Compare to Other Engine Types in Terms of Weight

What is the LS engine weight? When comparing engine types, weight is an important factor to consider. Lightweight engines are often more efficient and easier to install than heavier ones. The LS engine family is a popular choice for many vehicles due to its lightweight design and performance capabilities.

The LS engine family includes the 4.8L, 5.3L, 6.0L, 6.2L, and 7.0L variants that range from approximately 300-400 pounds in weight depending on the model chosen and accessories added on such as intake manifolds or exhaust systems. This makes them significantly lighter than other V8 engines such as the Ford Modular V8 which can weigh up to 500 pounds or more depending on the model chosen and accessories added on it as well as other large displacement V8s like the Chrysler Hemi which can weigh up to 600 pounds or more with all of its components installed in a vehicle’s engine bay.

In comparison to inline-four cylinder engines such as those found in Honda Civics or Toyota Corollas, LS engines are much heavier due to their larger size and additional components needed for their operation but they remain relatively light compared to other larger displacement V8s available today making them an attractive option for those looking for a powerful yet lightweight engine option for their vehicle build projects or daily drivers alike.

Overall, LS engines offer excellent power output while remaining relatively lightweight when compared with other types of engines available today making them an ideal choice for many automotive enthusiasts looking for a reliable yet powerful solution without sacrificing too much weight in their vehicle’s overall design. Particularly, among the best LS engine models and variants.

The Benefits of a Lightweight LS Engine for Performance Applications

Lightweight LS engines are becoming increasingly popular for performance applications due to their many benefits. These engines offer several advantages over traditional heavy-duty engines, making them an ideal choice for those looking to maximize power and efficiency.

- One of the primary benefits of lightweight LS engines is their weight. These engines are much lighter than traditional heavy-duty models, which can reduce the overall weight of the vehicle and improve its performance. This reduced weight also helps to reduce fuel consumption, as less energy is required to move the vehicle forward. Additionally, this reduced weight can help improve handling characteristics by reducing body roll and improving cornering ability.

- Another benefit of lightweight LS engines is their increased power output compared to heavier models. The lighter engine components allow for more efficient combustion, resulting in higher horsepower ratings and improved acceleration capabilities. This increased power output can be further enhanced with aftermarket modifications such as turbochargers or nitrous oxide systems that take advantage of the engine’s lightweight and efficient design.

- Finally, lightweight LS engines are often more affordable than heavier models due to their simpler design and fewer components required for assembly. This makes them an attractive option for those on a budget who still want a powerful engine that will provide reliable performance over time without breaking the bank in terms of cost or maintenance requirements.

In conclusion, lightweight LS engines offer numerous advantages over traditional heavy-duty models when it comes to performance applications such as racing or off-roading vehicles. Their reduced weight helps improve fuel economy while also providing better handling characteristics; they produce higher horsepower ratings than heavier counterparts; and they are often more affordable due to their simpler design requirements during assembly processes.

Understanding the Factors That Affect LS Engine Weight

The weight of an LS engine is determined by a variety of factors, including the type of engine, its components, and the materials used in its construction (as well as the numerous LS engine sizes and displacements). Understanding these factors can help you make informed decisions when selecting an LS engine for your vehicle.

- The type of LS engine is one factor that affects its weight. Generally speaking, larger engines tend to be heavier than smaller ones due to their increased size and complexity. For example, a 6.2L V8 will weigh more than a 4.8L V8 because it has more cylinders and other components that add to its overall mass.

- Another factor that affects the weight of an LS engine is the materials used in its construction. Aluminum blocks are lighter than iron blocks because aluminum is less dense than iron; however, aluminum blocks are also more expensive and may require additional maintenance over time due to their susceptibility to corrosion from moisture or chemicals in the environment. Iron blocks are heavier but typically last longer with less maintenance required over time compared to aluminum blocks.

- Finally, the components used in an LS engine can also affect its overall weight depending on their size and material composition as well as how they interact with each other within the system as a whole. For instance, larger camshafts or crankshafts will add additional mass while lightweight pistons or connecting rods may reduce it slightly depending on their design specifications and material composition (e.g., steel vs aluminum). Additionally, certain types of fuel injection systems may be heavier than others due to differences in design complexity or component size/weight ratios between them (e.g., port vs direct injection).

In conclusion, several factors affect the weight of an LS engine including the type/size of the engine block; materials used for construction; and components such as camshafts/crankshafts/pistons/connecting rods/fuel injection systems employed within it which all contribute towards determining how much mass it ultimately has when fully assembled into one unit ready for installation into your vehicle’s powertrain system setup accordingly for optimal performance output results desired from using such engines accordingly too then afterward too.

Exploring the Different Ways to Reduce LS Engine Weight

The weight of an engine is a major factor in the performance and efficiency of a vehicle. As such, reducing the weight of an LS engine can have significant benefits for both performance and fuel economy. There are several ways to reduce the weight of an LS engine, including using lighter materials, removing unnecessary components, and optimizing design features.

- One way to reduce LS engine weight is by using lighter materials in its construction. Aluminum is often used as a substitute for heavier steel components due to its strength-to-weight ratio. Additionally, composite materials such as carbon fiber can be used to further reduce the overall weight of the engine without sacrificing strength or durability.

- Another way to reduce LS engine weight is by removing unnecessary components from the design. This includes items such as air conditioning compressors, power steering pumps, alternators, and other accessories that may not be necessary for certain applications or vehicles. Removing these items can significantly reduce overall engine mass without compromising performance or reliability.

- Finally, optimizing design features can also help reduce LS engine weight while maintaining performance levels. This includes reducing wall thicknesses on certain components where possible without compromising structural integrity; utilizing lightweight fasteners; and designing parts with fewer machining operations which reduces material waste during production processes while still providing adequate strength characteristics for their intended use cases.

In conclusion, there are several ways to effectively reduce LS engine weight while still maintaining adequate levels of performance and reliability for most applications or vehicles requiring them. By utilizing lighter materials in construction; removing unnecessary components; and optimizing design features where possible; it is possible to achieve significant reductions in overall mass without sacrificing any important characteristics that make up a quality product.

Comparing the Weights of Different Generations of LS Engines

The LS engine family has been a staple of the automotive industry since its introduction in 1997 (and remains sought-after today, such as the LSA crate engines). Over the years, different generations of LS engines have been released, each with its own unique characteristics and performance capabilities. In this article, we will compare the weights of different generations of LS engines to give readers an idea of how they stack up against one another.

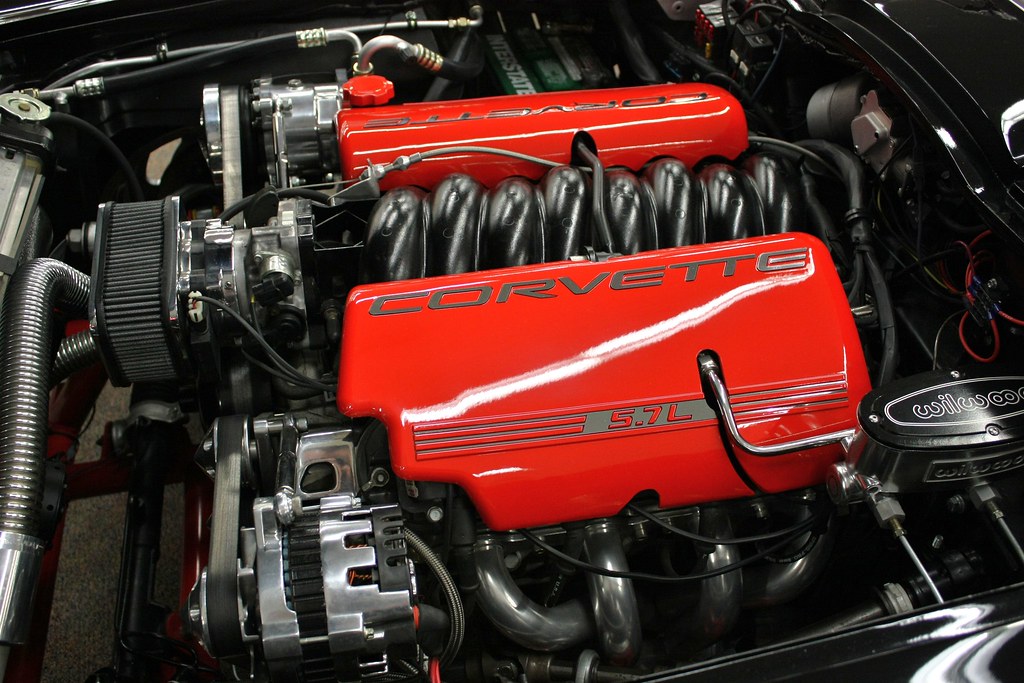

- The first generation LS1 engine was introduced in 1997 and weighed in at 364 lbs (165 kg). This engine was used in many popular vehicles such as the Chevrolet Corvette C5 and Pontiac Firebird Trans Am. It featured an aluminum block and heads, as well as a cast iron crankshaft for increased durability.

- The second generation LS2 engine was released in 2004 and weighed slightly more than its predecessor at 375 lbs (170 kg). This engine featured improved cylinder heads that allowed for higher compression ratios and increased power output. It also had a larger displacement than the previous model at 6 liters instead of 5.7 liters. The LS2 was used primarily in high-performance vehicles such as the Chevrolet Corvette C6 Z06 and Cadillac CTS-V series cars.

- The third generation LS3 engine came out in 2008 with a weight of 405 lbs (184 kg). This model featured an all-aluminum block design which allowed for greater power output while still maintaining lightweight characteristics compared to other engines on the market at that time. The larger displacement also helped increase power output from 430 horsepower to 436 horsepower when compared to its predecessor, the LS2 engine. The most popular vehicle featuring this motor is undoubtedly the Chevrolet Camaro SS/ZL1 models from 2010 onwards which utilized this powerful motor to great effect.

- Finally, we come to fourth generation LT1/LT4 engines which were released starting from 2014 onwards with a weight ranging between 441 – 454 lbs (200 – 206 kg) depending on whether it is an LT1 or LT4 variant respectively. These motors feature direct injection technology along with variable valve timing for improved efficiency over their predecessors while still providing excellent performance capabilities thanks to their higher compression ratios and larger displacements when compared to earlier models like those mentioned above. The most popular vehicle featuring these motors is undoubtedly again, the Chevrolet Camaro SS/ZL1 models from 2014 onwards which utilize these powerful motors effectively.

In conclusion, it can be seen that each successive generation of LS engines has become increasingly heavier due largely due to improvements made over time such as increased displacement sizes, direct injection technology, variable valve timing, etc. However, despite this increase in weight, they have still managed to remain competitively light when compared to other similar-sized motors available on today’s market.